A zero-carbon factory refers to the greenhouse gas emissions generated during production and service within a certain period of time (usually in annual units) within the greenhouse gas emission accounting boundary, calculated in accordance with carbon dioxide equivalent (CO2e), and on the basis of self-emission reduction as much as possible, the remaining emissions are eliminated by emission reduction projects outside the accounting boundary, and/or offset by a corresponding amount of carbon credits.

T/CECA-G 0171-2022 "Zero-Carbon Factory Evaluation Specification" divides zero-carbon factories into type I and type II according to the scope of greenhouse gas emissions neutralized within the boundary, and different types are further subdivided into different grades. For organizations that have set and implemented ambitious greenhouse gas emission reduction targets, the Zero Carbon Plant Evaluation provides the best channel for organizations to declare and demonstrate their greenhouse gas emission reduction performance.

NOA follows the third-party evaluation principles of objectivity, independence, honesty and trustworthiness, fairness and justice, professionalism and rigor, and conducts comprehensive investigation, supervision and verification of the compliance of the basic requirements related to the establishment of zero-carbon factories, the authenticity and accuracy of data, and guarantees The standardization and unity of the establishment of the main zero-carbon factory system.

○ T/CECA-G 0171-2022 "Zero Carbon Factory Evaluation Specification"

○ ISO14068-1 Climate Change Management Transition to Net Zero Part 1: Carbon Neutrality

○ PAS2060 Carbon Neutrality Demonstration Specification

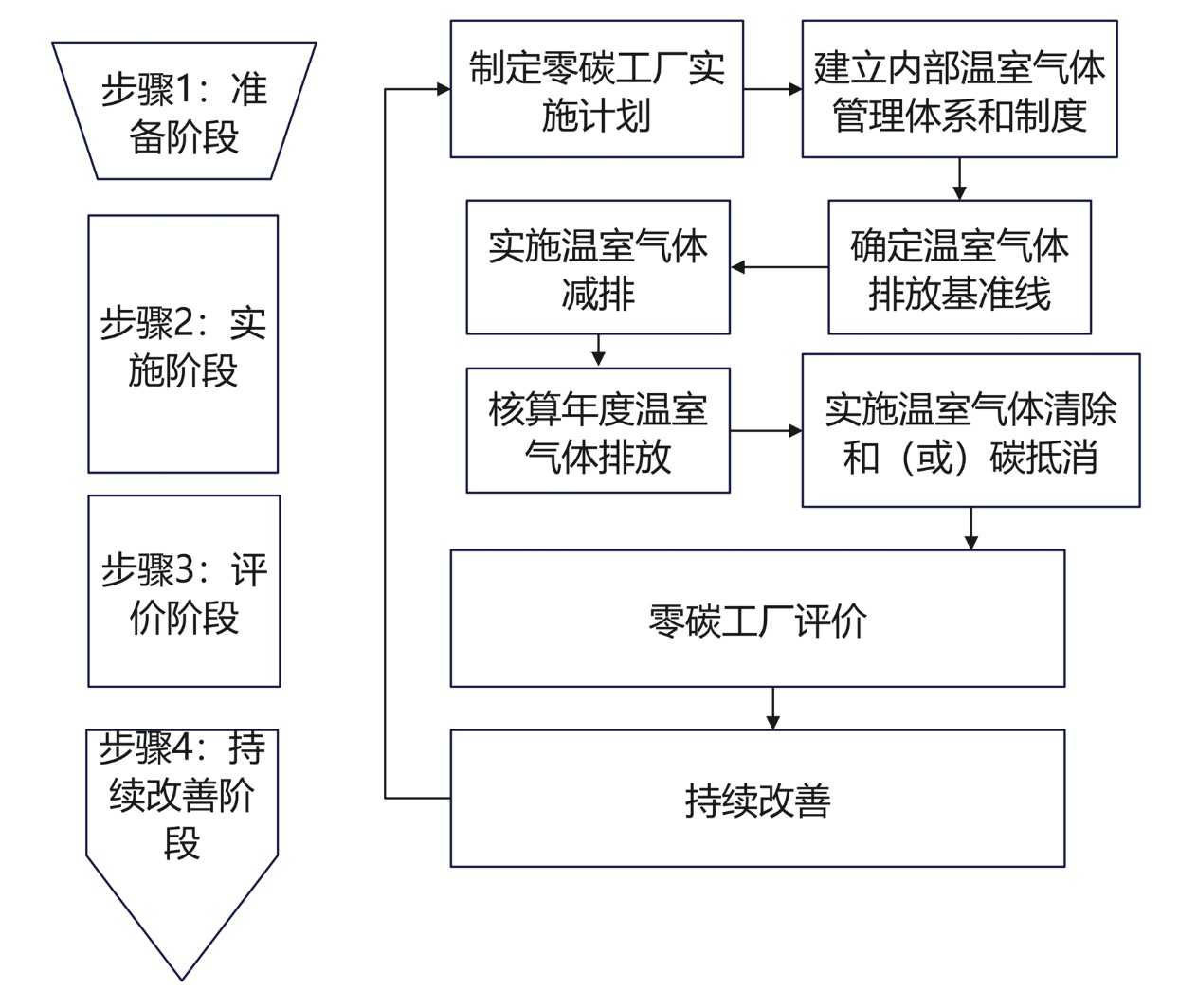

Conduct zero-carbon factory evaluation services for enterprises in accordance with the following procedures:

Type I, Type II: Respective grades: three stars, four stars, five stars, six stars;

Type I: Implement a zero-carbon factory strategy for Scope 1 and Scope 2 greenhouse gas emissions;

Tel:+86-400 821 5138

Fax:+86-21 3327 5843

Email:noa@noagroup.com