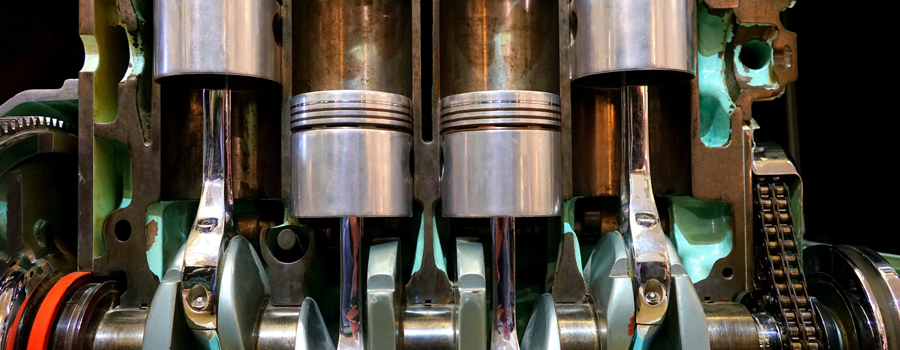

Metallic materials are materials that have properties such as lustre, ductility, easy conductivity and heat transfer. They are generally divided into two types: ferrous and non-ferrous metals. Ferrous metals include iron, chromium, manganese, etc. Non-ferrous metals are all metals other than iron, chromium and manganese.

Steel is the basic structural material, called the "bones of industry", non-ferrous metals are the basic materials for the development of the national economy, aviation, aerospace, automotive, machinery manufacturing, electric power, communications, construction, home appliances and most other industries are based on non-ferrous materials for production. With the rapid progress of modern chemical industry, agriculture and science and technology, the position of non-ferrous metals in human development is becoming more and more important. It is not only an important strategic material in the world, an important means of production, but also an important material for the indispensable consumer material in human life.

The composition and content of metals directly affect the performance and value of the material, and a range of standardised testing methods have been developed by countries and industry organisations for the study and testing of metals.

We use classical chemical analysis methods, modern advanced analysis and testing instruments, according to GB Chinese national series standards, American ASTM series standards, HB aviation series standards, GJB national military standard series standards, YB metallurgical industry series standards, YS non-ferrous metal series standards, ISO international series standards, XB rare earth industry series standards, SN commodity inspection series standards, JB Chinese machinery industry series accurate Analysis and testing of the chemical composition of various metallic and non-metallic materials; in-situ analysis for the study of material distribution, in-situ analysis for the study of material composition distribution, segregation, looseness, inclusions content, composition and particle size, phase analysis services for the study of the type of each precipitated phase, crystal structure, particle size distribution and composition of materials.

NOA has a central laboratory of nearly 30,000m2, with organic, inorganic, physical and chemical, thermal analysis, mechanics, reliability, combustion and weathering laboratories. We can provide one-stop analysis and testing services for metal materials and products, such as raw material quality control, composition analysis, foreign matter analysis, performance testing and reliability testing.

NOA can provide composition analysis, failure analysis, comparative analysis, foreign matter analysis and other services for metals and related materials through spectroscopy, chromatography and other large precision instruments, using multivariate analysis tools, to help customers analyse the chemical composition and composition content of samples, or qualitative and quantitative analysis of specified components and content according to customer requirements, identification of raw materials, additives, specific components, content and foreign matter composition and other analysis services.

I. Service offerings

|

Service offerings |

Common Products |

|

Pure metal |

Pure copper, pure gold, pure silver, pure titanium |

|

Alloy |

Nickel-based high temperature alloys, cobalt-based high temperature alloys, aluminium alloys, copper alloys, zinc alloys, magnesium alloys, titanium alloys, intermediate alloys |

|

Steel |

Carbon steel, stainless steel, cast iron, ferroalloys, low and medium alloy steel, stainless steel |

|

Metal ore |

Ferrous metal ores, rare metal ores, non-ferrous metal ores, precious metal ores |

|

Metallurgical raw and auxiliary materials |

Ores, deoxidisers, decarburisers, desulphurisers, refractory materials |

II. Services

|

Service |

Service Definition |

|

Chemical composition analysis |

Determination of the content of each element in the material to verify that it meets the content requirements specified in the standard; |

|

Coated coating test |

Tests for composition, thickness, adhesion, toughness, abrasion resistance, impact, condensation, optics, flame retardancy, ageing, etc.; |

|

Large-scale instrument testing |

ICP-MS, GD-MS, SEM and other instrumental tests |

|

Metallographic analysis |

Analysis of microstructure, grain size, non-metallic inclusions, phase composition, macroscopic low magnification, depth of hardened/carburized nitriding layers, etc; |

|

Failure analysis |

The integrated use of micromorphological analysis, compositional analysis, mechanical property analysis, process functional analysis and simulation replication tests; |

|

Mechanical properties |

Tensile, impact, hardness, bending, compression, fatigue and tube processability testing of materials in different environments; |

|

Ageing properties |

Tests for acid resistance, alkaline resistance, salt spray resistance and weather resistance of the coating; |

|

Thermal properties |

Determination of the coefficient of thermal expansion, thermal conductivity, etc. of materials; |

|

Corrosive properties |

Determines the ability of a material to resist corrosion by surrounding media. Salt spray, intergranular, stress corrosion, crevice corrosion of stainless steel, etc.; |

|

Environmental testing |

RoHS, REACH, California 65, halogen, hexavalent chromium, nickel release, food grade contact material testing, etc.; |

|

Raw material quality control |

Raw material purity testing, material characterisation, qualitative and quantitative analysis of specified components |

Tel:+86-400 821 5138

Fax:+86-21 3327 5843

Email:noa@noagroup.com